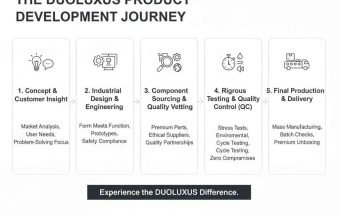

⚙️ Behind the Design: The 5-Step Journey of a DUOLUXUS Exclusive Product

In the world of fast-moving consumer electronics, it’s easy to focus only on the final product. But at DUOLUXUS, the journey from concept to consumer is a meticulous process. When you purchase a DUOLUXUS Exclusive item—whether it’s the rugged casing of the Panda speaker or the subtle elegance of a Pulse watch—you are investing in five critical steps of development.

Here is an inside look at the journey every DUOLUXUS product takes before it reaches your hands.

1. Concept and Customer Insight

The process begins not with a sketch, but with a need. We start by analyzing market gaps and, more importantly, customer feedback. For example, the need for a truly hands-free, multilingual experience led directly to the concept for our TranslateVue AI Glasses.

- Goal: Define the product’s core problem-solving function (e.g., better battery life, superior sound clarity, seamless translation) and establish initial design parameters.

2. Industrial Design and Engineering

This is where form meets function. Our engineers work closely with industrial designers to ensure the product is not only technically capable but also visually appealing and ergonomically comfortable for daily use.

- Prototypes: We move through multiple 3D-printed and functional prototypes. We obsess over the details: how does the watch band feel against the skin? Is the speaker grill durable enough for outdoor use? Does the interface feel intuitive?

- Safety and Compliance: All materials and components are vetted for safety and compliance with international electronic standards.

3. Component Sourcing and Quality Vetting

Quality is directly tied to the components used. While we operate on a global scale, we maintain strict control over who provides the parts that make up our products.

- Key Components: We focus on securing premium components, such as high-efficiency batteries for longevity, and advanced chipsets for fast, reliable Bluetooth performance.

- Supplier Partnership: We don’t just order parts; we build partnerships with suppliers who meet our high standards for ethical sourcing and material quality, ensuring that our commitment to quality starts at the microscopic level.

4. Rigorous Testing and Quality Control (QC)

Before any product moves into mass production, it faces a battery of brutal tests designed to simulate years of heavy use and common abuse.

- Environmental Testing: Products are subjected to extreme heat, cold, and humidity. Water-resistant speakers are submerged.

- Cycle Testing: Buttons are pressed thousands of times, charging ports are connected and disconnected repeatedly, and watch displays are struck to test their resilience. Only products that survive these tests move forward. Zero compromises are made here.

5. Final Production and Delivery

The last stage involves mass manufacturing on advanced assembly lines. However, our QC doesn’t stop here. We conduct random batch inspections and final functionality checks before a product is packaged.

- Packaging Focus: We design packaging that is both secure for shipping and provides a premium “unboxing” experience, ensuring the excitement of a new gadget starts the moment it arrives.

The result of this journey is the DUOLUXUS promise: a product where style, intelligence, and durability are engineered together for your best experience.

Add comment